The company

RubberGreen, recycled rubber specialist

Their mission:

To design and manufacture technical products from corporate waste.

Their needs

RubberGreen wanted to simplify, formalise and digitise its manufacturing and logistics processes.

However, it was essential that the procedure in Odoo be simple and quick to carry out while keeping full traceability of operations.

The solution

The complexity was therefore to find the best solution in Odoo to combine rapid encoding (with the use of scanners in particular) and complete encoding.

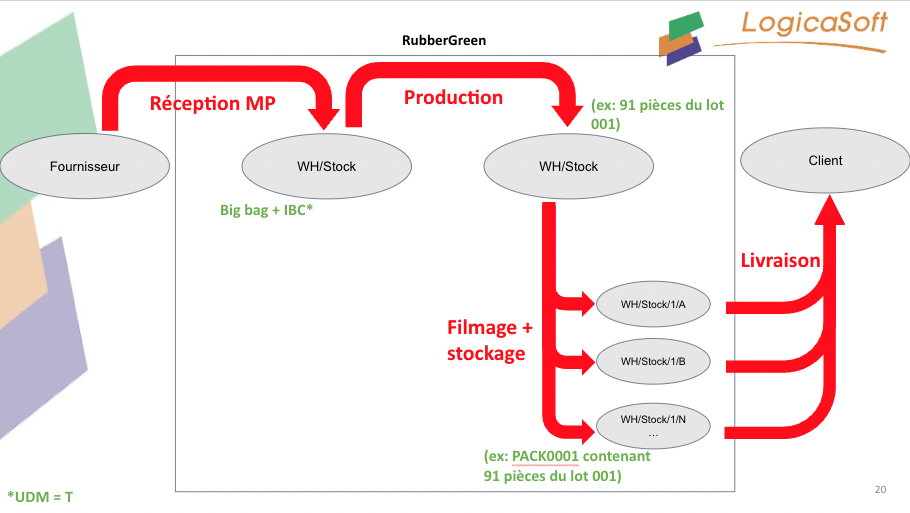

The LogicaSoft team therefore advised that a 4-step flow should be put in place.

1. Reception of raw materials

Management of raw materials such as aggregate big bags and glue IBCs in a specific unit of measure with a unique serial number. Each big bag of about 1 ton is characterized by a unique serial number. Thus, thanks to the new functionality of Odoo V15, it is very easy to generate these serial numbers automatically with one click.

Benefits:

• Avoid stock errors

• Ensure very accurate tracking within the warehouse

• Simplify the next step (consumption of these products by the operators)

2. Production (in 2 stages)

- Consumption of raw materials

Usually, in Odoo, the consumption of components is encoded manually when an operator validates his production (component by component).

In our case, we have created a new operation type "internal transfer" which directly records each item as consumed.

For those familiar with Odoo, this is a new type of transaction with an origin location of "WH/Stock" and a new destination location of virtual type named "Raw materials consumed".

Operators simply scan a one-ton big bag as soon as they take it to the production machine.

- Production of the finished product

Production is carried out via a "work order" with a screen perfectly adapted to be used by an operator on a tablet or touch screen.

This operation is, again, very fast because the raw materials have already been registered in the previous step.

3. Palletisation & storage

This step, which is managed as an internal transfer in Odoo, is interesting for two reasons:

- It makes it possible to distinguish between a finished product that leaves production and a finished product that is checked and ready to be delivered to the customer.

- Through the use of the "package" functionality, pallet tracking and picking is simplified. For example, instead of having 200 units of product A from lot 001, RubberGreen has 2 PACKS of 100 units each from lot 001.

4. Shipping

The preparation of orders is therefore also simplified thanks to the use of barcode scanners and the FIFO method, which will indicate to the storekeeper the oldest PACKS to be prepared before the transporter arrives.

5. Bonus

A critical point in this type of project, which includes manufacturing and logistics, is the management of the labels that are printed and stuck on the products at the different stages of the process.

After several projects where LogicaSoft advised and implemented work orders, packaging and barcode functionality, we developed a generic module to meet this need.

Basically, three labels are generated at raw material reception, at the last stage of the work order and at palettisation with packages.

These labels include the information and barcodes needed to move quickly from one operation to the next using a scanner.

RubberGreen